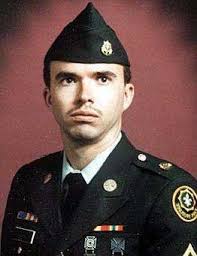

Editor’s Note: The other day at the Exxon station across from Nissan, I found myself staring at the plant where I worked for eight years, lost in memories. Even the street Exxon is located on—Sgt. Asbury Hawn Way—held memories. I trained Sgt. Hawn myself, though I knew him simply as Freddie back then. After grinding through five years on night shift, I’d earned my spot on days, and Freddie was hired to step into my place on nights. A few years later, Freddie, stopped by our car business and told me he was deployed to Iraq and he needed a truck. In another twist of irony my late mother overheard him and asked if we can pray for him—sadly, he never returned home.

Freddie was assigned to the 3rd Squadron, 278th Armored Cavalry Regiment, Tennessee Army National Guard, McMinnville, Tenn was killed on Aug. 14, 2005 in Tuz, Iraq, when his Humvee came under attack by enemy forces using rocket-propelled grenades and small-arms fire in Tuz, Iraq

Standing there with the gas pump in my hand, a question hit me:

What if Nissan had never chosen our small town?

Where would I be today? Where would any of us be?

Nissan has been a genuine blessing to our community. The plant—along with the suppliers and businesses that came with it—pulled countless families out of poverty, including mine.

I was just a kid working at the Omni Hut Restaurant when Nissan announced its $300 million investment in Smyrna. As a 13-year-old busboy, I remember overhearing customers and Major and Sally Walls talking excitedly about the big news of Nissan coming to Smyrna. Yes, there was anxiety too—uncertainty about what this massive Japanese company would mean for our small town.

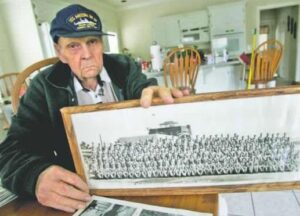

Major James Walls, who owned the restaurant and lived next door to us, often gave me rides to work. His iconic Polynesian restaurant quickly became a regular meeting spot for Nissan’s Japanese executives, who conducted business over dinner. Ironically, Major Walls had been stationed at Pearl Harbor during World War II, yet I never once heard him speak with bitterness toward the Japanese. The Omni Hut’s theme captured it perfectly: “Created in a million miles of travel.”

Nissan didn’t just bring jobs to Smyrna—it brought hope and a future many of us never imagined. It lifted families like mine out of poverty and transformed our small town. But standing on Sgt. Asbury Hawn Way that day, I was reminded that prosperity comes with sacrifice.

Freddie took my place on the night shift so I could move up. Those five years of night shift had been rough—mentally and physically—but Freddie stepped in without hesitation. When he stopped by our dealership before his deployment to Iraq, my mother prayed for his safe return. Most of her prayers were answered throughout her life. This one wasn’t. Freddie never came home.

Major Walls survived Pearl Harbor and later welcomed his former enemies to his table, understanding that progress requires looking forward without forgetting the past. As Nissan faces unprecedented challenges today, I think about all the workers and families who built their lives around that plant. Some gave their time and sweat. Freddie gave everything.

Nissan is going through a turbulent time. Let’s remember that Smyrna’s future remains deeply tied to Nissan’s future, and pray that both endure.

_______________________________________________________________

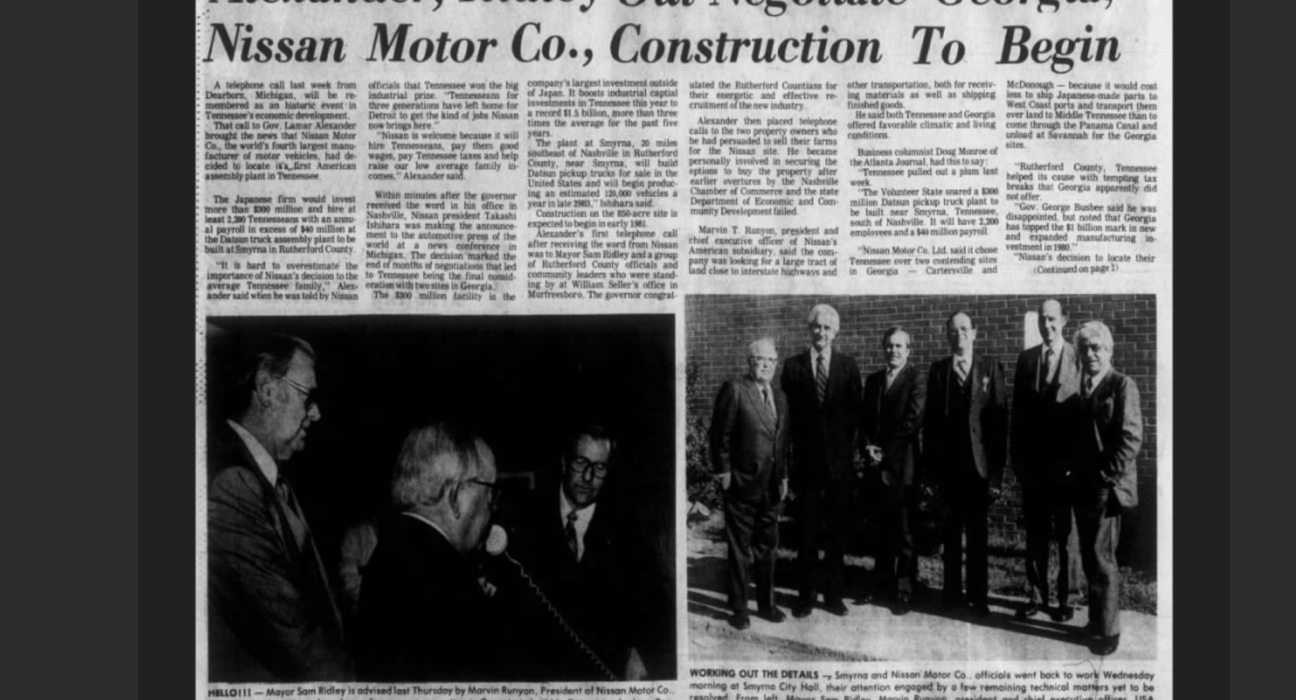

By Douglas Williams

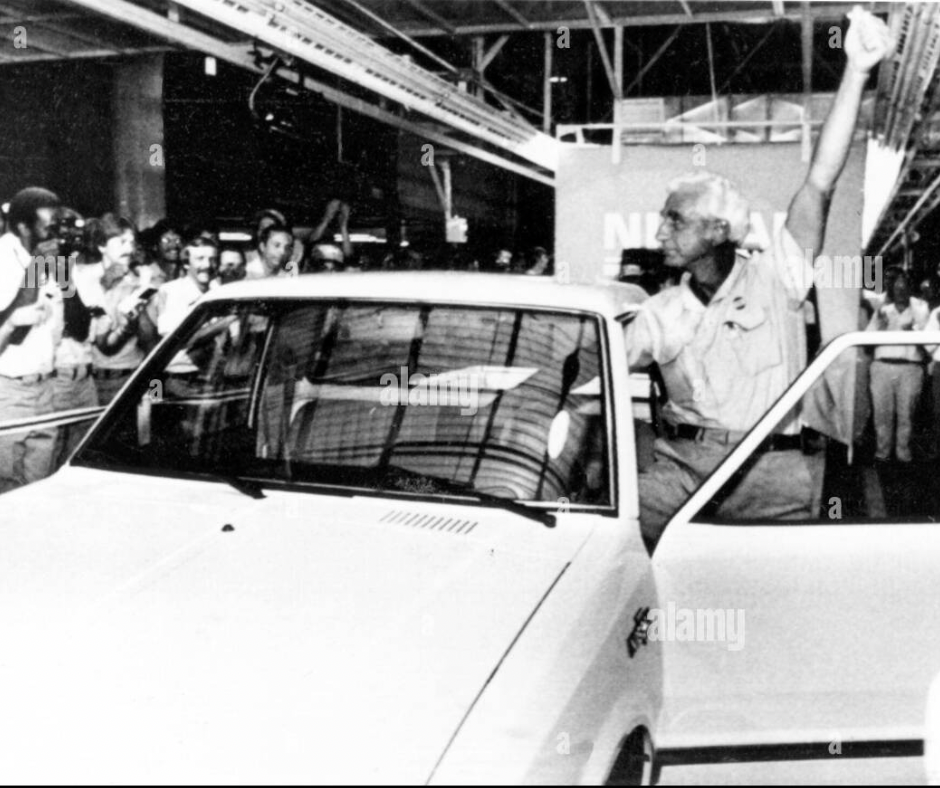

DEARBORN, Oct. 30, 1980 — Nissan Motor Manufacturing Corp. announced here today that it will build its $300 million, 2,200-employee truck assembly plant in Smyrna, Tenn., just outside of Nashville.

According to Takashi Ishihara, president of Nissan Motor Co. Ltd. (Japan), the investment is the giant automaker’s largest ever outside of its home country.

Get a curated selection of 10 of our best stories in your inbox every weekend.

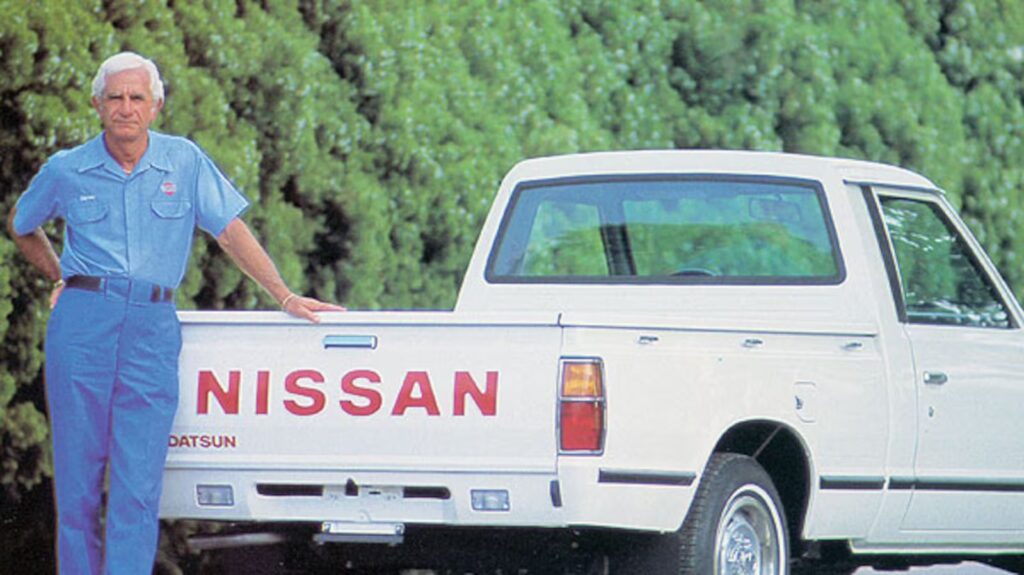

Marvin T. Runyon, until recently a top-ranking Ford Motor Co. manufacturing executive and now head of Nissan’s American manufacturing operations, said the choice of the site was made only Monday. The cost of transportation to and from Nashville gave that city the edge over Atlanta in the final decision, he said.

Runyan said the Great Lakes region and sites in the Southeast had been considered earlier, and the possible sites were narrowed down to three places, all in the Southeast, a few months ago. The facility will produce an estimated 120,000 trucks a year, using imported, Japanese-made power trains and other parts, Runyan said.

About 35 percent of the finished product will be made in the United States initially, he said. California and the Southeast each account for approximately 35 percent of Datsun’s sales, Runyan said.

The American plant will manufacture three front-wheel-drive versions of the Datsun pickup: the standard one, the 4-by-4 and the King Cab.

The Nissan executives said ground would be broken for the new plant within a couple of months and full production would be expected by the fall of 1983.

Ishihara read his initial statements in English and then took questions, with the answers quickly translated from Japanese by an aide in this unusual press conference. The Nissan executive said Datsun trucks account for roughly 20 percent of Nissan’s u.S. sales. He said the imposition of a 25 percent import tax on commmercial vehicles has not yet hurt Datsun truck sales but that he and other Nissan executives expect the tax to have an effect sometime soon.

Whatever happens on the tax front will not change the Japanese automaker’s plans, Ishihara said.

Leave feedback about this